Masala grinding is an essential part of the spice industry, and to ensure the right texture, consistency, and flavor, using the right machine is crucial. Impact Pulverizer Machines are commonly used for grinding masalas due to their efficiency, accuracy, and ability to produce fine-quality powder. These machines are specially designed to grind dry and coarse materials like spices.

In this blog, we’ll look at the Top 5 Benefits of Using Impact Pulverizer Machines for masala grinding, and how they can improve the grinding process for masala manufacturers.

1. Superior Grinding Efficiency and Consistency

One of the major benefits of using an Impact Pulverizer Machine is its efficiency in grinding spices. These machines use high-speed rotating hammers or blades to crush the spices into fine particles. The powerful impact breaks down the spices effectively and quickly.

- Efficiency: The high-speed action of the machine allows for fast grinding, while generating very little heat, which helps preserve the natural flavor and aroma of the masalas.

- Consistency: The Impact Pulverizer Machine ensures uniform grinding, meaning the size of the ground spices remains the same across different batches. This uniformity is essential to deliver consistent flavor and texture.

This makes Impact Pulverizers ideal for masala production, where quality and consistency are very important.

2. Retention of Flavor and Aroma

Spices like turmeric, garam masala, and red chili have strong flavors and essential oils. When spices are ground using traditional methods, these essential oils may be lost, affecting the flavor. Impact Pulverizer Machines preserve the essential oils in spices by grinding them at high speeds using sharp blades.

- Flavor and Aroma Retention: The Impact Pulverizer Machine helps keep the spices’ natural oils intact, which means the final ground masala will retain its original flavor and aroma. This is important because the taste of masala directly impacts the taste of food.

By using this machine, masala manufacturers ensure that their products are flavorful and aromatic, which meets customer expectations, especially in the highly competitive spice market.

3. Energy Efficiency and Cost-Effectiveness

Another key benefit of Impact Pulverizer Machines is that they are energy-efficient. These machines are designed to produce a high output while consuming less energy.

- Energy Savings: Compared to traditional grinding methods, Impact Pulverizers consume less energy to grind the same quantity of spices. This is particularly beneficial for businesses that grind large amounts of masala daily, as it helps in reducing energy costs.

- Cost-Effectiveness: Since these machines increase production efficiency and reduce energy usage, they help lower overall operational costs. This makes them a cost-effective choice for masala producers who want to produce more with less energy and labor.

This helps manufacturers maintain a balance between cost and quality, which is crucial for running a profitable business.

4. Versatility and Customization

Impact Pulverizer Machines are versatile and can be used to grind a variety of spices and dry materials. This flexibility makes them a great investment for masala manufacturers.

- Wide Range of Applications: These machines can grind various types of spices such as coriander, cumin, chili, garlic, and more. They can also handle other dry materials like herbs, grains, and powders used in different industries.

- Adjustable Settings: Most Impact Pulverizer Machines allow users to customize the grinding size. Whether you need a fine powder for baking or a coarser grind for curry powders, the machine can be adjusted to suit the specific needs of the product.

This versatility is important for masala manufacturers who need to produce different types of products or cater to various customer preferences.

5. Low Maintenance and Durability

Impact Pulverizer Machines are known for their durability and low maintenance needs. These machines are built to last, and they require minimal attention to continue functioning effectively.

- Durability: These machines are made with strong, high-quality materials such as stainless steel, which resist wear and tear. They can handle heavy use for long periods without losing performance.

- Low Maintenance: Unlike other machines that require frequent servicing, Impact Pulverizer Machines are relatively easy to maintain. With regular cleaning and occasional checks on blades and motors, they can continue to perform at a high level for years.

By reducing maintenance costs and downtime, manufacturers can keep production running smoothly and efficiently.

Conclusion

In summary, Impact Pulverizer Machines offer several important benefits to masala manufacturers. From superior grinding efficiency and consistent quality to energy savings, versatility, and low maintenance, these machines help improve the grinding process and ensure high-quality products.

For masala producers looking to enhance their production and deliver top-quality products, investing in an Impact Pulverizer Machine can be a game-changer. It not only improves efficiency and preserves flavor but also offers cost savings and long-term reliability.

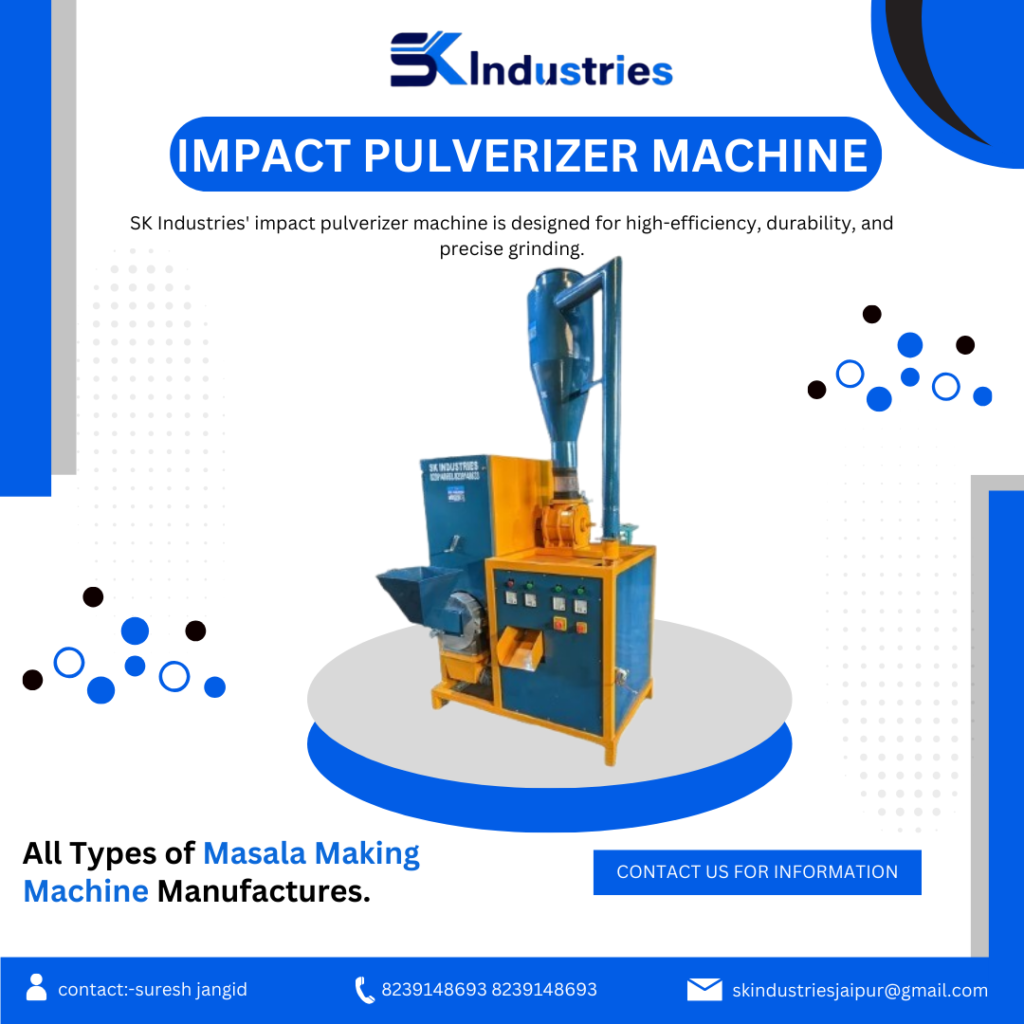

If you are a masala producer looking to streamline your grinding process, an Impact Pulverizer Machine from a trusted manufacturer like SK Industries is an excellent choice.